After learning to work with a CAD software called Onshape, I was eager to utilize my new skills to build a CO2 dragster designed for speed.

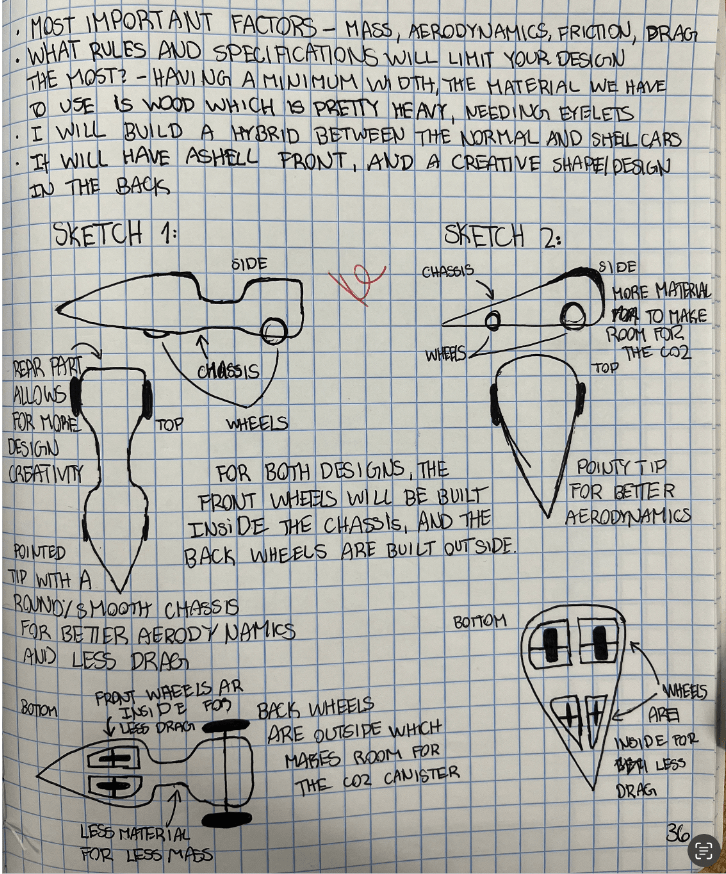

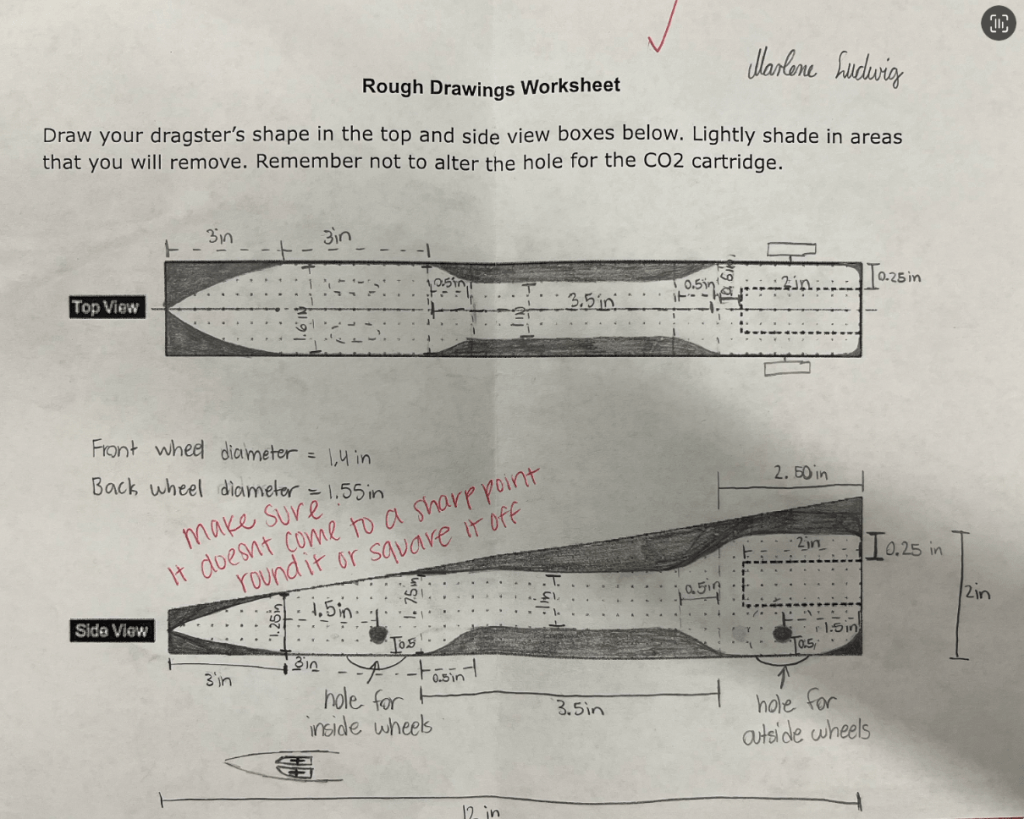

The first step I took was to research this topic by going online and looking at examples of dragsters created by other people. This allowed me to gain some prior knowledge and tricks, such as drilling the axle holes before cutting the body to align them better. I also brainstormed what factors would affect my dragster’s performance. The factors that would affect my dragster the most are friction, weight, and drag. Friction and drag are forces that slow down my dragster. Friction is directly proportional to weight, so mitigating weight will result int less friction and a faster car. In order to reduce drag, my dragster needed to be aerodynamic. Carefully considering this information, I had a couple ideas of what my dragster would look like. For example, I knew that I wanted my dragster to be as round and light as possible so that the above factors are reduced. By drawing quick sketches of two designs, I was able to bring my ideas onto paper.

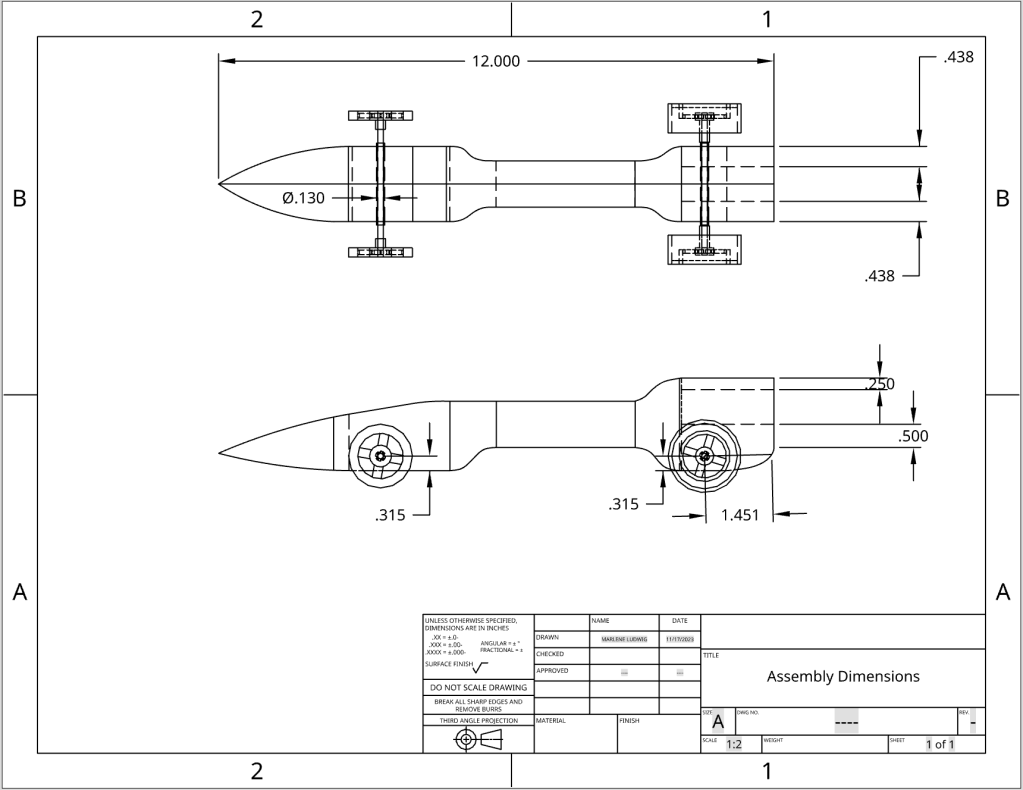

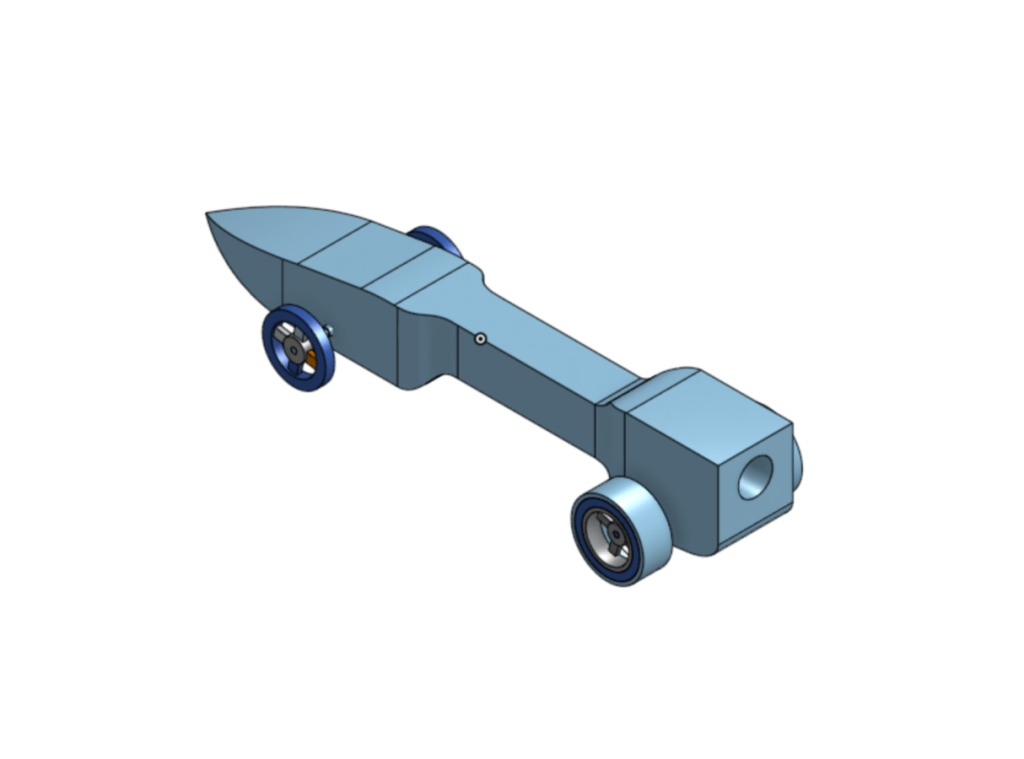

Using the Onshape CAD software, I began to construct my prototype. Since I was building the prototype online, it was very important to maintain the corresponding measurements to make sure that the finale prototype was to scale. Presenting my prototype with two different angles allowed me to better visualize the final product. Below you can see a 3D version of my finalized prototype. The model consists of 2 front wheels, 2 back wheels, 2 axles, and 2 bushings. The wheels, axles, and bushings are connected in such a way that allows them to spin. This is to best simulate what my actual dragster would look and move like.

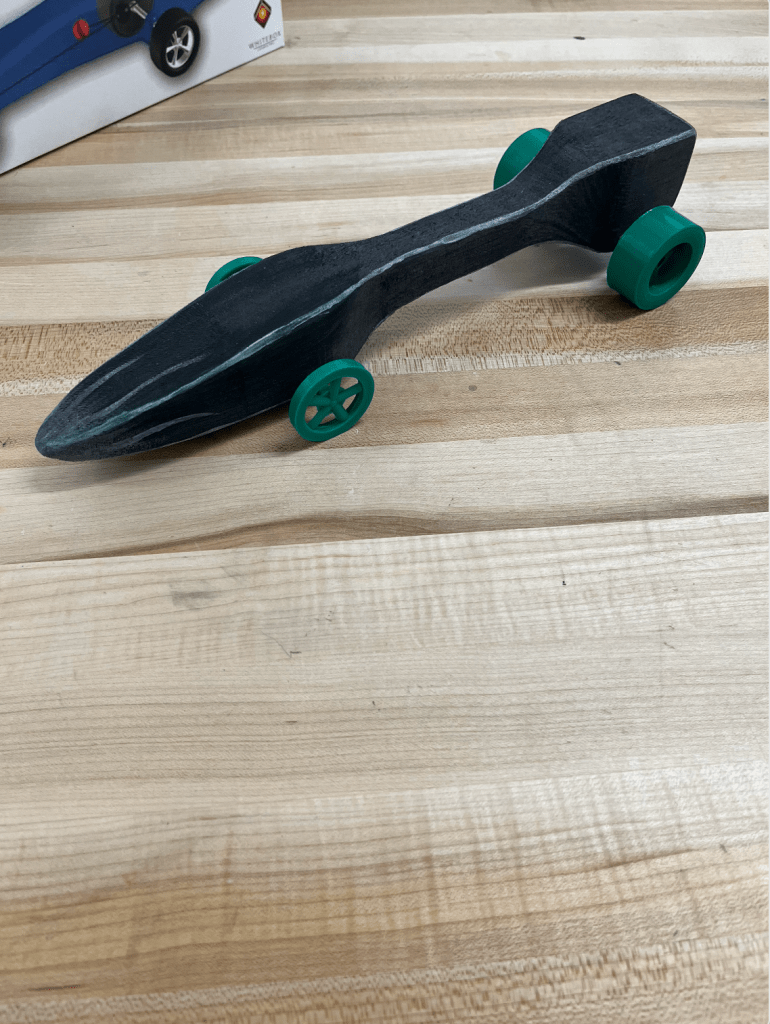

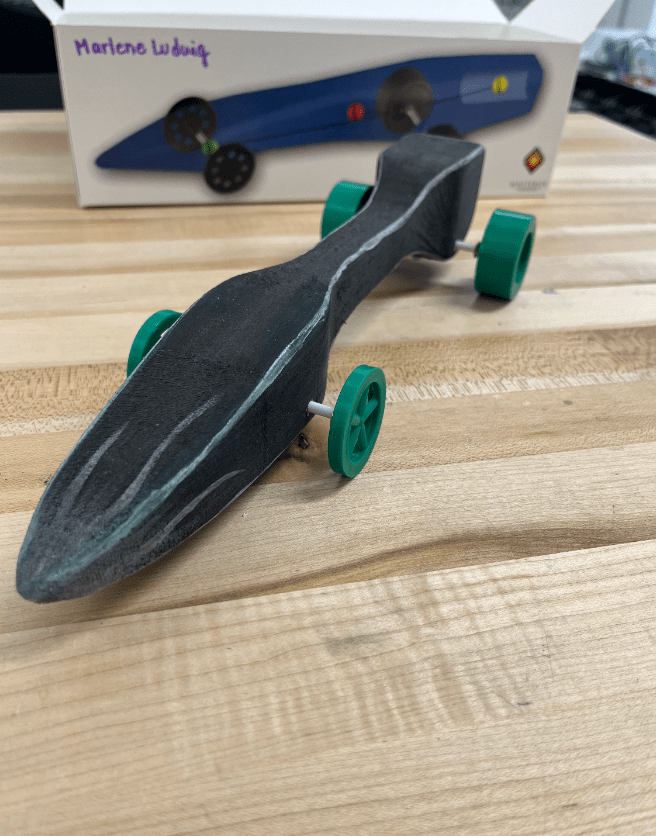

Next, I built and tested my finished dragster prototype. My dragster performed well with a race time of approximately 0.7 seconds over 6 meters. This translates to a speed of 31 km/h. You can see my finished dragster to the right. Overall, the axles, bushings, and wheels were definitely the parts that slowed my dragster down the most. I am very happy with my body design, but I would make a few tweaks (such as removing more material from the front) if I were to repeat this project. My body design incorporated elements from a shell car and a normal car. This resulted in reduced air resistance when racing, which translated to a fast average speed.